Our Approach

ALGS’ Manufacturing Division is the central and primary division of our tri-fold company. This division’s unique product line represents a true paradigm shift for the construction industry. While the heart of our product line is our computer-aided design (CAD) system, which provides the factory with accurate, concise shop drawings for production, the true revenue generator is our computer controlled manufacturing plant that produces the walls, floor joists and trusses. Our advanced manufacturing systems result in a more cost effective and efficient building processes.

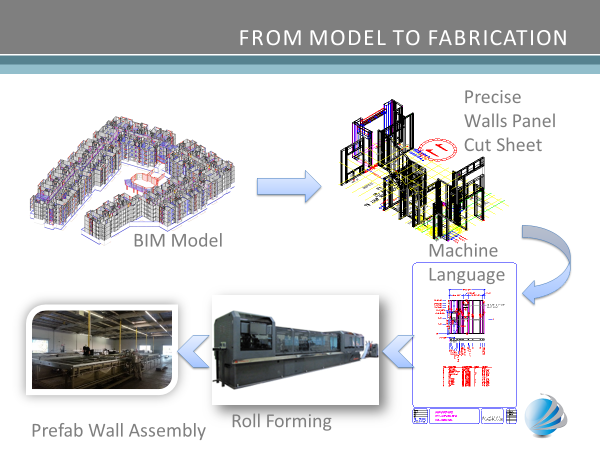

From the BIM model, the information is disseminated directly to ALGS’ Roll Forming machines in a form of CNC panel drawings, which produces the wall, floor, and truss panel components up to 12 GA and inkjet each with the precise wall information and location in the building. This process eliminates the need for off the shelf stud and track materials. It also eliminates the dependency on the experience of the labor force in laying out and cutting of all the wall panel components. All of which insures the maximum efficiency and quality control of all and each part of the framing system.

Part of our success is dependent upon our manufacturing production flow. We have developed a factory system that virtually eliminates confusion, work stoppages and bottlenecks, thus maximizing our throughput, continuity and ultimately our competitive edge.

Next Steps…

To request a quote or Advanced LGS product catalog.