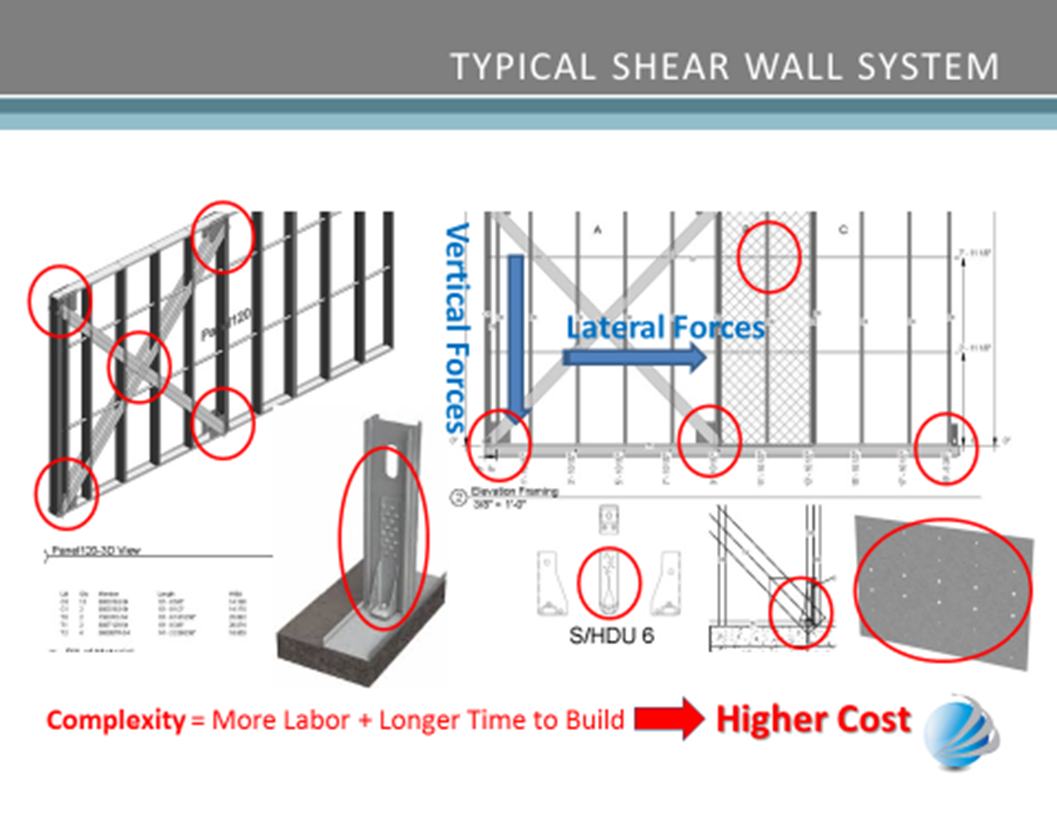

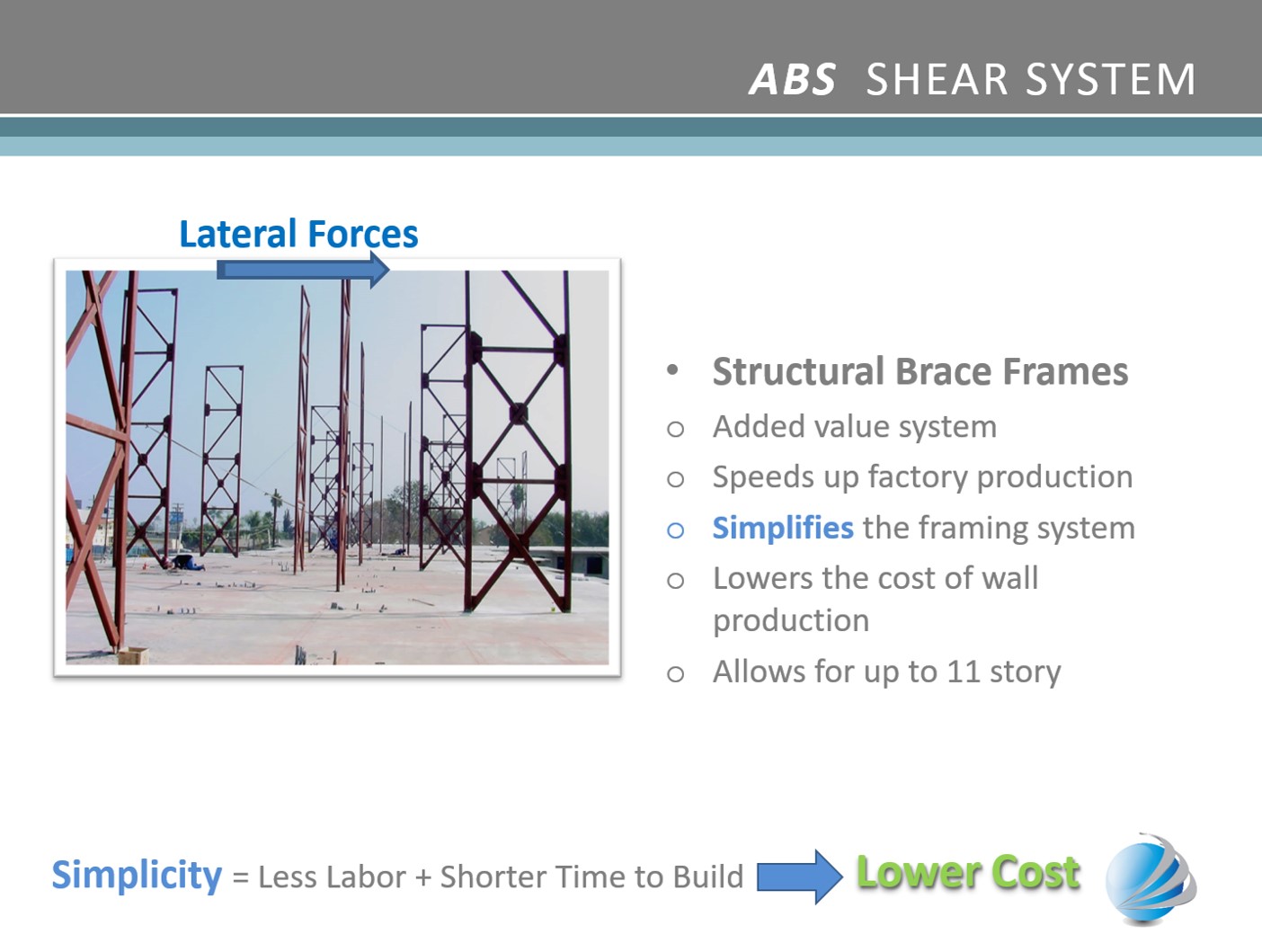

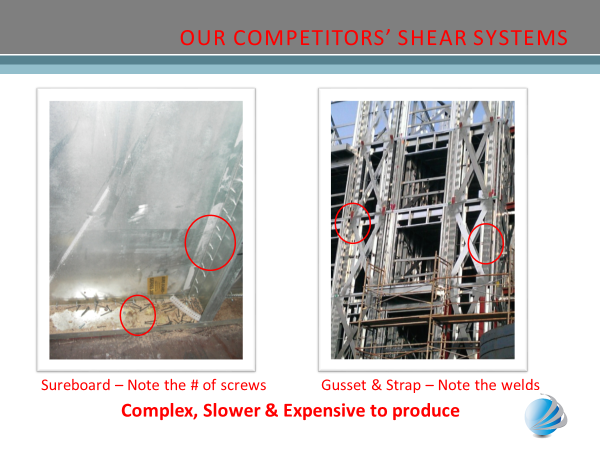

As a manufacturer, ABS is capable of producing all the Light Gauge Steel Framing panels according to the project original structural design and working drawings. In addition, ABS would collaborate with the structural engineer to incorporate the structural steel brace frame lateral system instead of the traditional shear wall components (i.e. flat straps, gussets, hold downs, anchor bolts and/or Sure-board). ABS realized that by simplifying the panel production and field installation it was able to lower cost to produce while increasing the efficiency of the project structural design. All of which allows ABS to very competitive and extend the cost savings to its clients.

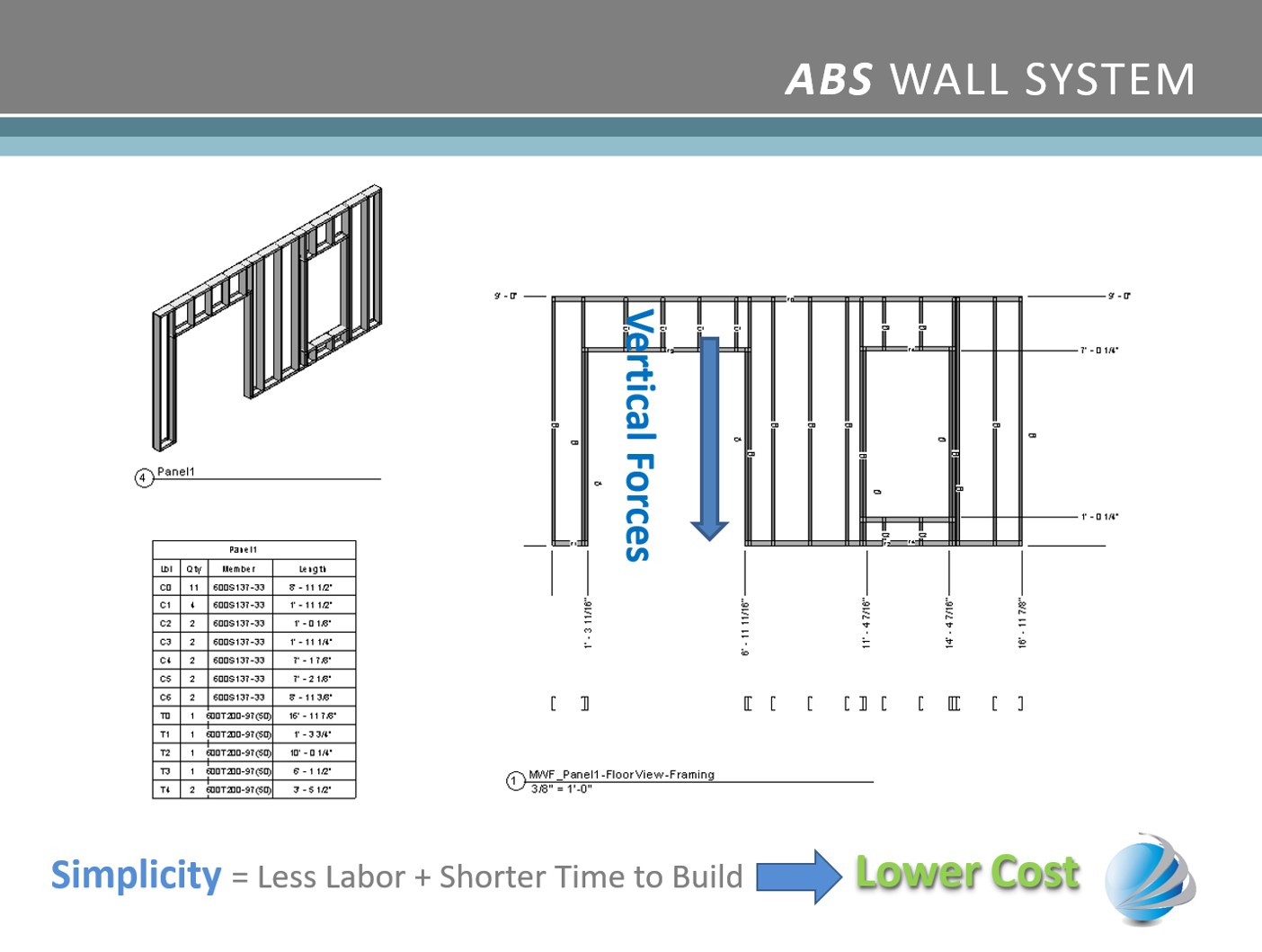

To further illustrate our recommended system, please note that light gauge steel walls can handle the gravity forces of much higher structures. But the challenge for many has always been to design the walls to handle the gravity load and lateral forces as well. ABS realized early on that by eliminating the shear from the walls, the design possibilities are endless. And that is the main reason that our structural design calls for separating the gravity loads from the lateral forces. The ABS walls are designed to handle the gravity load while utilizing the structural brace frames and/or moment frames at strategic locations throughout the structure to handle the lateral forces. Additionally, by designing a rigid diaphragm flooring system, engineers are able to shift the shear requirement to the central core as it is typical in concrete high-rise buildings. This process eliminates the need for shear walls at the exterior of the building and allows for increase in the glazing percentage of the skin which adds to architectural design possibilities.