ABS is a groundbreaking solution that is set to transform the construction industry utilizing its factory-built Light Gauge Steel Modular Units. In the face of traditional site-built wood construction, these innovative modular units offer unparalleled advantages in terms of speed, sustainability, durability, and cost-effectiveness.

Speed and Efficiency

Factory-built Light Gauge Steel Modular Units are manufactured off-site in controlled environments, ensuring precision and efficiency. This results in significantly faster construction timelines compared to traditional wood construction. The modular units are assembled with meticulous attention to detail, reducing on-site labor requirements and accelerating project completion, saving time and money for developers.

Sustainability

In an era where sustainable practices are imperative, Light Gauge Steel Modular Units shine as an eco-friendly alternative. Steel is recyclable, and the modular construction process generates less waste compared to the traditional on-site methods using wood. Choosing steel modules is a commitment to reducing environmental impact and promoting a greener, more sustainable future.

Durability and Structural Integrity

Light Gauge Steel is renowned for its strength and durability, offering a robust and resilient alternative to traditional wood construction. Steel modular units are not susceptible to issues such as rot, warping, or termites, ensuring longevity and minimizing maintenance costs over the lifespan of the structure. This increased structural integrity also enhances safety, making it an ideal choice for a wide range of applications.

Cost-Effectiveness

Investing in Light Gauge Steel Modular Units proves to be a cost-effective decision in the long run. The streamlined manufacturing process, reduced construction time, and minimal on-site labor requirements contribute to overall project cost savings. Additionally, the durability of steel ensures lower maintenance costs over time, making it an economically sensible choice for developers and investors alike.

Design Flexibility

Light Gauge Steel Modular Units offer unparalleled design flexibility, allowing architects and builders to create innovative and customizable structures. The precision of factory manufacturing enables intricate designs, and the modular nature of the units allows for easy expansion or modification, accommodating the evolving needs of the end-users.

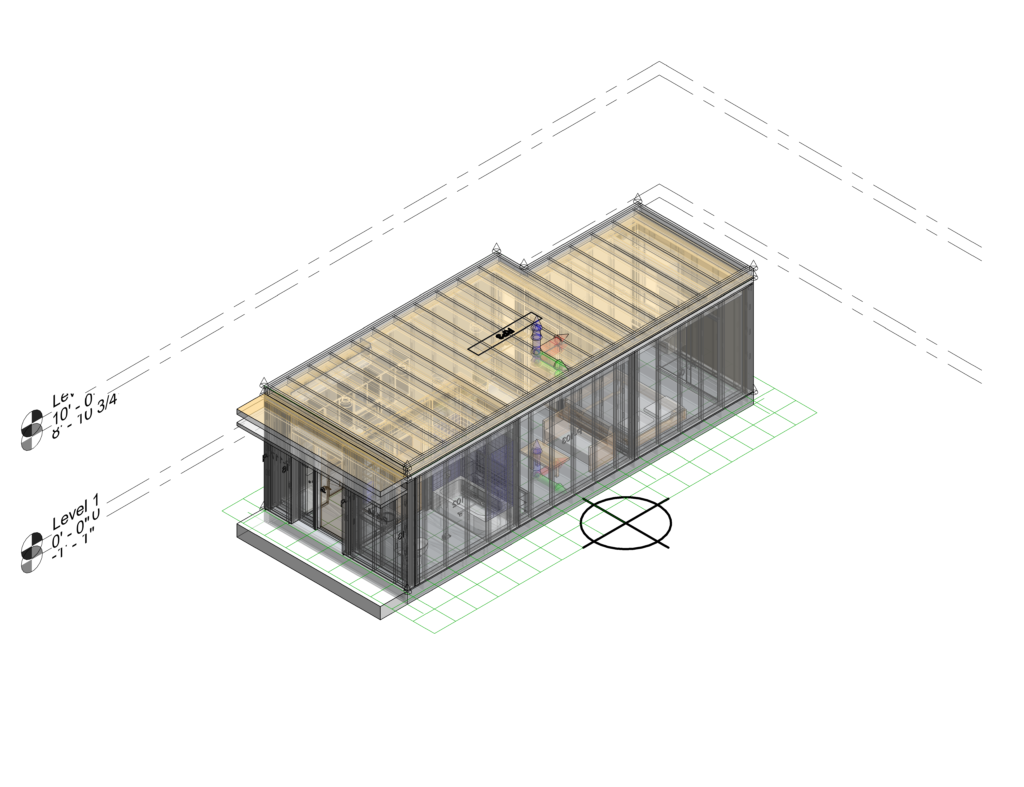

Sample of a 400 sf one-bedroom apartment.

Total Set Time: 8 Days

- 84 (1 Bedroom) Modular Apartment Units

- 10 Modular Stairs

- 4 Modular Elevator Lobbies

- 4 Modular Trash Chutes

Process

The ABS process is modeled after the Henry Ford assembly line which allows for an increase of productivity and quality control. Unlike a typical construction site or other modular builders, ABS controls its production by producing the framing systems in-house using its Roll formers to increase efficiency and lower its waste to 0.5%. This also allows ABS to procure coil steel months in advance to avoid any dependency on supply chain disruptions and cost unpredictability.

Assembly drawings are used by the factory production lines using CNC machines and production methods. As-built drawings and equipment schedules become embedded in the O and M manual making it easy to identify parts for maintenance schedules.

ABS task-oriented process allows for ease of employee training and increase of efficiency.

Technological

ABS use of templates and jigs in a factory environment provides greater accuracy and tolerances particularly when used with CAD design systems.

Conclusion

In conclusion, the transition from traditional site-built wood construction to factory-built Light Gauge Steel Modular Units represents a paradigm shift in the construction industry. This innovative approach offers a winning combination of speed, sustainability, durability, and cost-effectiveness. Embracing this change not only ensures a more efficient and environmentally friendly construction process but also positions us at the forefront of a new era in building technology. Let’s build a better future together with Light Gauge Steel Modular Units.