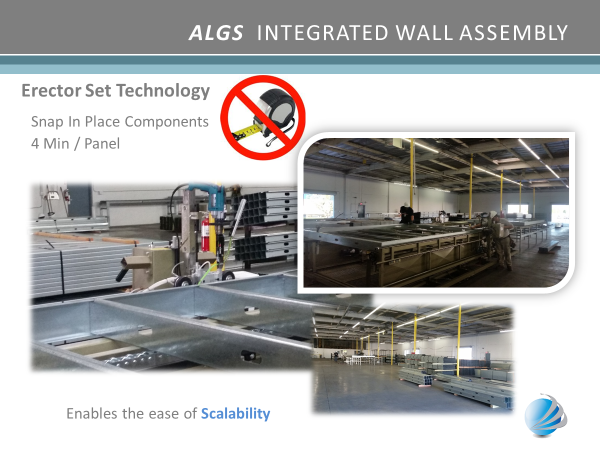

Wall Panels Assembly

Each wall component is bundled and sent to the assembly production line where the assemblymen pre-fit the wall components together utilizing the pre-notched grooves. The wall is then sent to the semi-automated assembly table to create the particular panel under compression. From the production assembly, the walls are staged ready for shipment to the job site. By utilizing brace frame lateral system in the field to provide the building with both strength and shear protection ALGS reduces the amount of work and experience level needed to produce the wall panels. This process also provides the project with an advanced framing method, safer, lower in cost, and reduces the framing schedule by 50% with third of the labor force needed in the field at a much lower skill level.