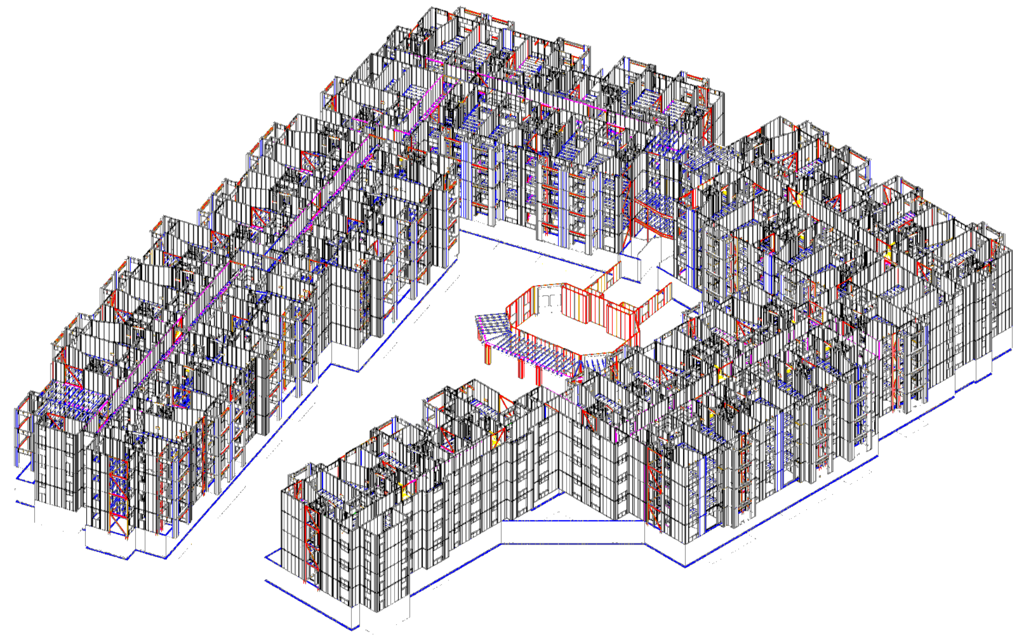

BIM

Each project begins within ABS’ BIM (Builders Information Modeling) department, which goes through a very extensive computer model creation of every framing component in the project. This allows for the discovery of any discrepancy on the engineer’s and architect’s working drawings, which in turn reduces the field discoveries, delays, and change orders. Then the information is disseminated directly from the computer model to the project team of engineers, architects, and contractors to ensure the efficiency of ABS’s process is translated efficiently to the field for all the sub-trades. The information is also disseminated directly to ABS’ Roll Forming machines, which produces the wall, floor, and truss panel components up to 12 GA and inkjet each with the precise wall information and location in the building. This process allows ABS to ensure that the precise design is translated into machine language and all the framing components are produced directly with our roll forming machines eliminating human interpretation and errors.